Perry Baromedical's Hyperbaric Systems are FDA approved for over 60 years

Perry Baromedical's Hyperbaric Systems are FDA approved for over 60 years

Acrylic Window Aging – Maintenance & Inspections

We at Perry Baromedical would like to thank you for your purchase of a Perry Baromedical Hyperbaric Chamber. Whether you’re a first time customer or a long-term member of the Perry family, we truly hope your facility is enjoying a successful operating program and that you have been able to treat your patients in a manner that has helped them through difficult recoveries.

As the end-user of a PVHO chamber (Pressure Vessel for Human Occupancy), and according to the requirements contained within the Operator’s Manual, ASME/PVHO-2 (Clause 1-2.1, Clause 1-6.1), NFPA 99 (National Fire Protection Association Clause 14.3.1.3.2), and the FDA (US Food and Drug Administration – implicit operators responsibilities pursuant to the manufacturers statement of specified servicing under FDA 21CFR Part 820, Subpart N, Section 820.200), your facility is responsible for developing and implementing a maintenance program that will specifically address and satisfy the requirements for the proper inspection of the acrylic window (in addition to the general chamber maintenance requirements). The purpose of this memo is to alert you of these and additional requirements specifically in regards to the acrylic window as the window nears the end of the 10-year design life. It is strongly suggested that you obtain copies of the above referenced documents and read them thoroughly.

These controlling standards, and in particular, PVHO-2, Section 2 (Viewports), Clause 2-4.1, calls for (1) an operational acrylic window inspection based on daily usage, and (2) a more comprehensive maintenance inspection based on design life. Prior to end of design life, in addition to daily inspections, the acrylic window would also be inspected annually, based on the maintenance schedule listed in the Operators Manual. As the acrylic window reaches 10 years of age (or 10,000 cycles, whichever comes first), the inspection requirements become much more stringent and expand to include the need for additional specific documentation. The need and frequency of this inspection schedule is outlined in PVHO- 2, Clause 2-4.3, and is specified at a maximum interval of 24 months after the end of the design life (PVHO-2, Table 2- 4.3-1).

Under normal conditions a 10-year inspection results in a satisfactory review and the chamber is certified to remain in service for an additional (1) year period, with a scheduled re-inspection each year thereafter for a total possible life span of 20 years (or 20,000 cycles, whichever comes first). However it’s important to know that acrylics do age and eventually require replacement. And because of the costs involved, knowing this well before you face the need to do such a replacement will assist you in accurately costing your treatment profiles over the long term.

Please keep in mind that at any time during the annual inspection process (prior to end of design life), if a determination is made that the acrylic has failed the (above referenced) PVHO requirements, and cannot be repaired, or it is in need of replacement based on the applicable standards, the inspecting firm is required to red tag the machine and prohibit its continued use for human treatments. Fortunately, outside of cases of specific trauma to the acrylic window, the aging process is usually gradual and windows can be monitored monthly or quarterly should an anomaly be found during an inspection.

We realize that this inspection and possible “red tag” may severely impact your facilities operating capabilities, but the first priority is patient safety and the requirements under which these devices are built, manufactured, and maintained.

Should you like additional information on the requirements of the referenced code specifications, information on possible inspection programs, or just wish to discuss the general aspects of the chamber servicing requirements, please contact either Perry Baromedical’s Engineering

or Customer Service departments at your earliest convenience.

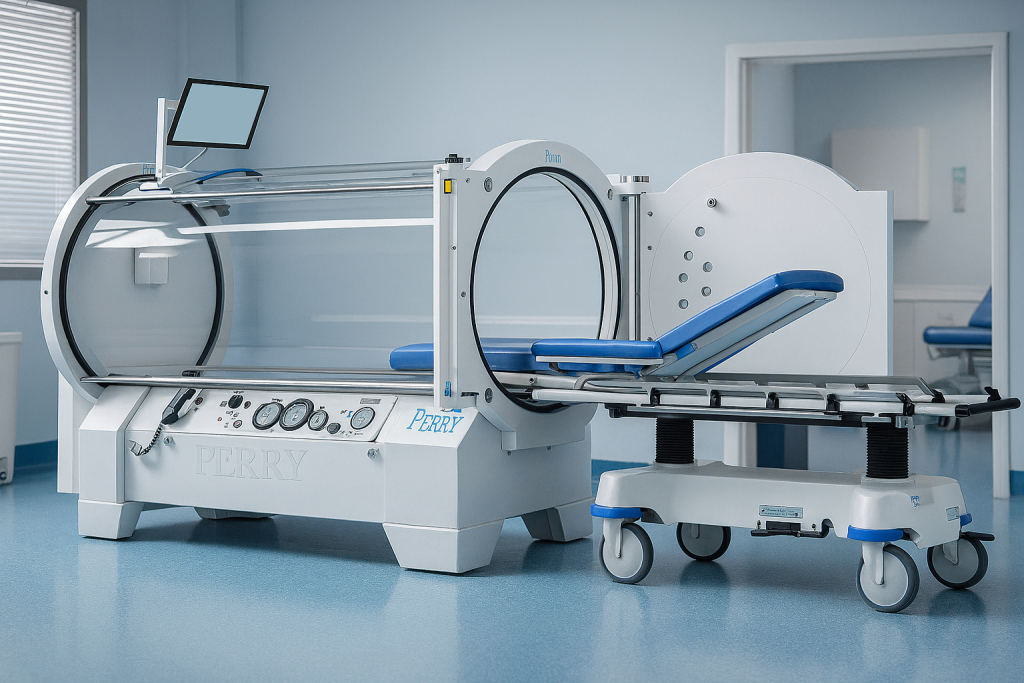

The SIGMA Series Monoplace chamber is intended to be used by prescription only by trained personnel.

The following are general safety requirements regarding chamber operation, the operator of the device and patient safety:

Safety: Chamber Safety

The SIGMA Series monoplace chamber is safe to operate when used as directed, however, the increased pressure inside the chamber, and use of 100% oxygen, requires that the Owner/User take the time to fully understand the operational and functional aspects of the system, including any added cautions associated with operation of the system as a pressure vessel. The increased pressure and the use of 100% oxygen mandate that the Owner/User understand the risks involved. The service requirements and maintenance schedules provided to the owner/user are intended to provide the guidance and instructions needed to maintain the chamber within operational specifications. Perry Baromedical requires that service be performed by suitably trained technicians, who have demonstrated proficiency with the system. This is necessary to mitigate risks associated with the system and assure the Owner/User that the system is maintained in proper working order.

Personner:

All personnel who will operate the hyperbaric chamber should be thoroughly trained in its use and have a good working knowledge of hyperbaric oxygen therapy in general. The selection of competent and experienced personnel is critical to safe usage of hyperbaric chamber systems. The physician in charge should be trained and proficient in the application of hyperbaric oxygen treatment.

Patient Safety:

The user organization should develop and follow its own operating safety procedures, consistent with good medical practice.

Performance:

The SIGMA Series Monoplace Hyperbaric Systems provide HBOT hyperbaric oxygen therapy for a single patient with maximum operational pressures of 3 ATA or 30 psig in conformance with applicable IEC 60601-1, NFPA 99, and FDA 21CFR, Chapter 1, Part 820 requirements. The pressure vessel is designed in accordance with applicable ASME & PVHO design codes. The standard system is pressurized with USP Medical Grade Oxygen and pressurization with breathing air is possible using a wall mounted air/oxygen select valve manifold assembly.

The SIGMA Series systems are equipped with an adjustable height patient gurney stretcher system to provide patient entrance into and out of the chamber. The stretcher gurney assembly mates with the chamber and locks into position. Once the gurney is locked, the patient may be rolled into and out of the chamber on the stretcher. Once the door is closed and latched a safety gas interlock allows flow of oxygen and chamber pressurization. A second interlock prevents the door from being opened while the vessel is pressurized.

An operator control panel is provided equipped with the necessary gauges, indicators, and controls necessary for the safe operation of the system. Controls consist of totally pneumatic components, and include adjustable pressurization, depressurization, and ventilation. A 50-90 psig oxygen source is required for standard operation. Features are described below.

The SIGMA chamber system is equipped with a voice communication system consisting of an externally mounted control module and an internally mounted speaker / microphone. An auxiliary input connection is provided to accept an audio input from a radio or TV for patient entertainment.

Standard features:

Controls and instrumentation:

| PARAMETER | Sigma 34 | Sigma 36 | Sigma 40 |

|---|---|---|---|

| Maximum Operating Pressure | 30 PSIG (66 FSW), 2.07 bar (3 ATA) | ||

| Design Temperature | Operating and Storage: 32°F to 100°F, 0°C to 38°C | ||

| Relative Humidity | Operating: >50%, Storage: 20% to 70% | ||

| Oxygen Supply Pressure | 50 to 90 psig, 3.45 to 6.2 bar | ||

| Oxygen Supply Flow | 30 scfm / 850 lpm | 40 scfm / 1130 lpm | 40 scfm / 1130 lpm |

| Air Supply Pressure (Air Pressurization) | 50 to 90 psig, 3.45 to 6.2 bar | ||

| Air Supply Flow (Air Pressurization) | 30 scfm / 850 lpm | 40 scfm / 1130 lpm | 40 scfm / 1130 lpm |

| BIBS Supply (Air or O₂) | 50 to 90 psig, 3.45 to 6.2 bar | ||

| BIBS Supply Flow (Air or O₂) | 3.5 scfm / 100 lpm | ||

| Ventilation Rate | 4.4 to 13.6 scfm / 125 to 385 lpm | ||

| Pressure Change Rate | 1 to 5 psi/min / 0.07 to 0.34 bar/min | ||

| Emergency Depressurization Rate | 0.3 psig/sec (approx.), 3 ATA to 1 ATA in 120 sec | ||

| System Pressure Gage | 0 – 100 ± 3% psi | ||

| Set Pressure Gage | 0 – 30 ± 0.5% psi | ||

| Chamber Pressure Gage | 0 – 30 ± 0.5% psi | ||

| Ventilation Gage | 125 to 385 ± 2% lpm | ||

| Treatment Tolerance | ±1 PSI | ||

| Maximum Patient Weight | 500 lb / 227 kg | 700 lb / 318 kg | 700 lb / 318 kg |

| Overall Length | 105 in. / 2.667 m | ||

| Length with Undercarriage | 113 in. / 2.870 m | ||

| Overall Width | 40 in. / 1.016 m | 42 in. / 1.067 m | 46 in. / 1.168 m |

| Height | 61 in. / 1.549 m | 64 in. / 1.626 m | 68.75 in. / 1.746 m |

| Height with Undercarriage | 65.5 in. / 1.663 m | 68.5 in. / 1.740 m | 73.25 in. / 1.861 m |

| Internal Diameter | 33.5 in. / 0.851 m | 36 in. / 0.914 m | 40.5 in. / 1.029 m |

| Internal Length | 90 in. / 2.286 m | 93 in. / 2.362 m | 93 in. / 2.362 m |

| Internal Volume | 47.2 cu. ft. / 1.337 m³ | 58.4 cu. ft. / 1.551 m³ | 69.3 cu. ft. / 1.962 m³ |

| Weight | 2200 lb / 998 kg | 2400 lb / 1088 kg | 2850 lb / 1293 kg |

| Weight with Undercarriage | 2450 lb / 1112 kg | 2650 lb / 1202 kg | 3100 lb / 1406 kg |

| Gurney Dimensions | 30.25 x 85.37 x 33.79 in. (768.4 x 2168.4 x 858.3 mm) | ||

| Mattress Dimensions | 21 x 75 x 3.125 in. (533.4 x 1905 x 79.4 mm) | ||

**Supply pressure and flow rates are identical for the standard oxygen press or the optional air press system. Please consult Perry Baromedical if the optional air press system is selected. Note: Peak flows are indicated, at maximum pressurization rates.